Learn how ISCAR’s innovations in direct cooling and chipbreaker geometry are reshaping tool performance, process stability, and surface quality. In the world of metal cutting, the key to efficient, high-quality machining lies in two critical factors: thermal management and chip control. At ISCAR, engineers have tackled both challenges simultaneously by developing advanced internal coolant delivery systems alongside high-performance chipbreakers. The result is a cutting-edge (literally) solution that delivers smoother operations, longer tool life, and superior surface finishes, even under the demanding conditions of mass production.

Direct Cooling – Born from a Real Need

The challenge was set for ISCAR’s Turning and Groove-Turn development teams: design tools that offer

smoother cutting, greater process stability, extended tool life, and improved surface finish, particularly

in mass production environments. The solution centered around an innovative approach to coolant channel

design—optimizing outlet angles, exact positioning, and flow rate—to achieve exceptional results in

targeted, high-efficiency cooling.

Advantages of Direct Cooling to the Cutting Edge

1. Significant Heat Reduction on the Insert

Excessive heat causes plastic deformation of the insert, altering its geometry and negatively impacting

machining accuracy, surface finish, and tool life. Direct cooling maintains a stable temperature at the

cutting edge, preventing these effects (Fig. 1).

2. Efficient Chip Evacuation

Improper chip evacuation leads to part damage, built-up material, and unnecessary cutting forces. Focused

cooling facilitates continuous chip flow, improving process stability and surface quality.

3. Prevention of Built-Up Edge Formation

Difficult-to-machine materials tend to stick to the cutting edge, forming a built-up edge. Direct cooling

significantly reduces this tendency, keeping the cutting zone clean and effective.

4. Maintaining Dimensional Stability of Long Parts

Direct cooling lowers overall temperature, helping prevent thermal distortion and bending in long or slender

components.

Coolant Channel Design – A Precise Science

Though internal coolant channels are hidden from view, their impact is dramatic. ISCAR develops smart

coolant geometries that deliver fluid precisely to the cutting zone. This targeted cooling (Fig. 2) extends

insert life, reduces machine downtime, shortens setup time, and optimizes the overall machining process.

Chipbreakers – The Critical Link to Machining Success

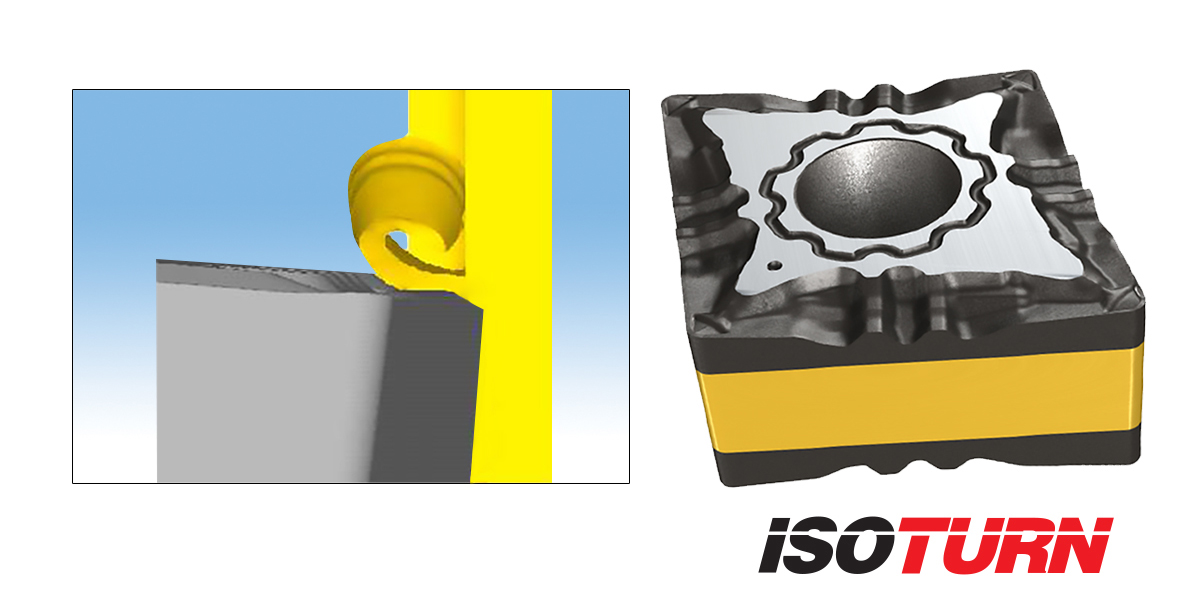

The chipbreaker is a fundamental component with a direct impact on cutting performance. Despite its vital

role, its importance is often overlooked. One of the most common challenges in machining is poor chip

control, especially during finishing, semi-finishing, or operations involving variable cutting depths. ISCAR

has taken the lead in this domain by developing new chipbreaker geometries (Fig. 3) suitable for a wide

range of materials, including steel, stainless steels, and superalloys.

How a Chipbreaker Works

Chipbreakers with an arched groove near the cutting edge force the chip to curl and break into a short

length. This prevents chip entanglement, reduces vibrations, extends tool life, and minimizes tool breakage.

Effective chip breaking also lowers resistance, decreases heat generation, and slows insert wear. A

well-designed chipbreaker contributes directly to longer insert life and improved process reliability (Fig.

4).

Choosing the Right Chipbreaker – Material, Conditions, and Application

When selecting a chipbreaker, several parameters must be considered:

• Material type (e.g., steel, stainless steel, superalloys)

• Cutting conditions: cutting speed (vc), feed rate (f), depth of cut (ap)

• Required surface quality: Finishing or roughing operations

The proper combination of chipbreaker design and direct cooling is the key to machining accuracy, consistency, and efficiency.

Conclusion

ISCAR remains committed to developing intelligent solutions that deliver real value to its customers. Direct

cooling at the cutting edge, combined with application-specific chipbreaker geometries, represents a

technological leap that enhances every critical performance metric—from tool life to surface quality.

Coolant channel design and chip control are no longer optional; they are the foundation of modern metal

cutting.