Determining which drilling operations qualify as deep drilling is not straightforward.

Traditionally, operations involving holes with a depth-to-diameter ratio of 5 or greater were considered deep drilling.

However, advancements in metal cutting technology have extended this level to holes with depths of 10 or even 12 times the diameter.

Today, the term “deep drilling” refers not only to the production of particularly deep holes, but also to the specialized methods used for both relatively “short” and truly “deep” holes.

In addition to the challenges present in all drilling operations, deep drilling has its own specific difficulties.

One major issue is problematic chip evacuation.

In deep drilling, chips that become clogged in the machined hole worsen the surface finish and may cause drill breakage.

The "pecking" drilling method can help, but it decreases productivity and increases machining costs.

Another challenge is restricted coolant supply, which not only reduces the cooling and lubrication needed for effective cutting but also affects chip evacuation.

Also, decreased drill rigidity can lead to drill deflection, drill "walking," and vibrations - all of which negatively impact machining accuracy and tool life.

These challenges drive the development of advanced deep drilling tools.

New designs focus on efficient and reliable chip removal to prevent clogging, targeted coolant supply to improve cooling and lubrication and to contribute to efficient chip evacuation, increased tool rigidity to withstand bending and vibration loads, and the use of advanced cutting materials to boost tool life.

As a result, innovations include optimized flute geometries, enhanced chip-splitting cutting edges, sophisticated internal coolant channels, state-of-the-art coatings for carbide grades, and other new features.

The latest products expanding ISCAR’s deep drilling tool line exemplify these ongoing innovation trends.

New Carbide Grades Improve Wear Resistance

Recently, ISCAR introduced two new carbide grades specifically developed for BTA deep drilling tools.

The first, IC948, is intended for machining steel and stainless steel (ISO P and ISO M application groups) using drilling heads with brazed carbide tips or indexable inserts.

This grade features a submicron substrate and a nano-layered TiAlCrN PVD coating, providing high resistance to oxidation wear and chipping.

The second grade, IC8355, is designed primarily for drilling carbon and alloy steels, as well as martensitic and ferritic stainless steels (ISO P application group) by using heads that mount indexable inserts.

Its multi-layer CVD coating, combined with a post-coating treatment, enhances resistance to abrasion and fracture wear, resulting in prolonged tool life when machining at medium to high cutting speeds.

Extra-Long Solid Carbide Drills Boost Machining Performance

Solid design predominates in deep drills with small diameters, typically up to 12 mm.

Naturally, a one-piece structure offers the highest rigidity among accessible solutions.

However, maximizing stiffness, ensuring effective chip removal, and providing precise coolant supply in small-diameter solid deep drills present considerable difficulties, especially given the limited design options available.

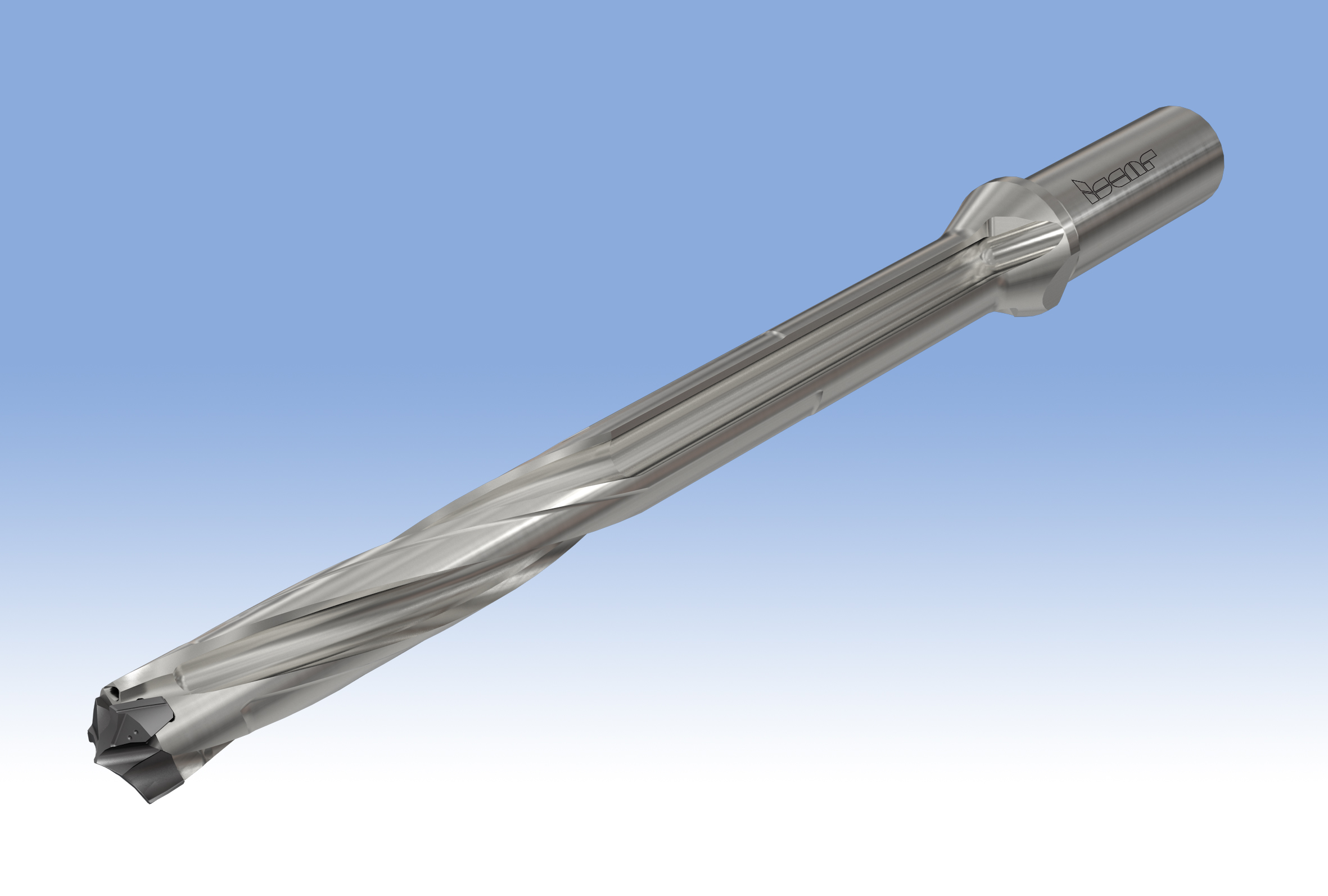

ISCAR’s latest additions to the solid carbide deep drill program include extra-long twist drills with cutting depth-to-diameter ratios of 30, 40, and 50, corresponding to diameter ranges of 3–10 mm (.125-.391"), 3–8 mm (.125-.312"), and 4–6 mm (.172-.250"), respectively.

The drills have a 135-degree point angle, double-margin design, polished flutes, and helical internal coolant channels.

These integrated features enable stable and productive drilling of deep holes of small diameters in solid components, made mainly from steel (ISO P application group).

Recently, ISCAR has expanded the solid deep drill family by new drills for machining cast iron (ISO K application group).

The drills incorporate polished flutes and coolant channels, as mentioned above, and also feature a triple-margin design and a low flute helix to further increase rigidity and optimize drilling performance - including applications with inclined entrances or exits, as well as cases with cross holes (Fig. 1).

The introduced drills are available in diameters ranging from 3–12 mm (.125-.472"), with cutting depth-to-diameter ratios of 16, 20, and 30.

It is important to note that balancing requirements are not limited to the tool assembly comprising the tool body, inserts, and clamping elements such as screws.

The entire tooling system - including the tool assembly, the basic adaptor mounted in the machine tool spindle, and any intermediate elements (extensions or reducers) - must be balanced.

This rigorous requirement is emphasized also in the ISO 16084 standard.

Three-Flute Concept for Higher Productivity

When looking to enhance the productivity of a standard two-flute drill after all other options have been explored, increasing the number of flutes is an intuitive next step that comes to mind.

However, raising the metal removal rate (MRR) requires more space for effective chip evacuation – in other words, a larger flute volume, which diminishes structural behavior of a drill, especially in long-reach applications.

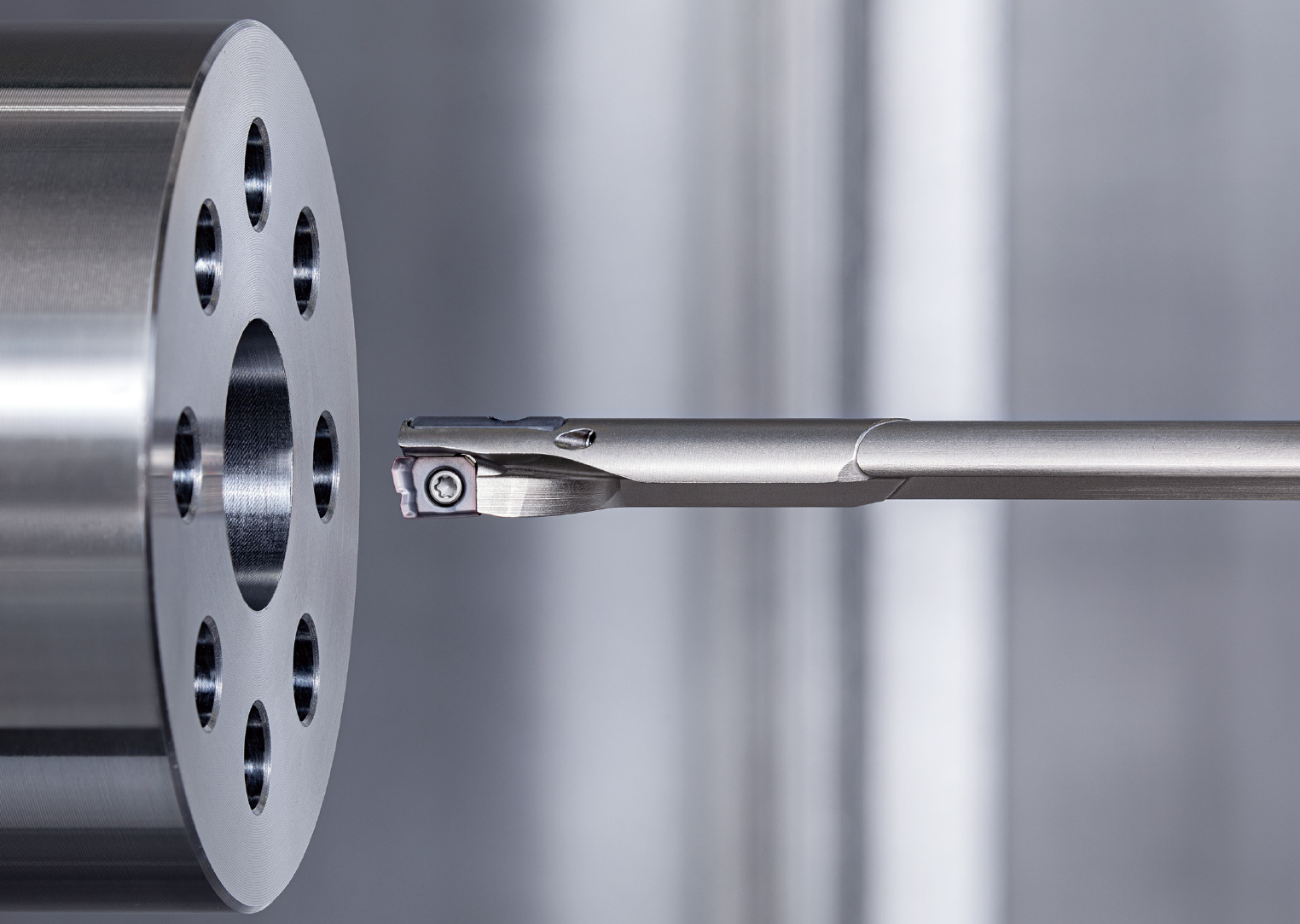

The latest addition to the QUICK-3-CHAM family of assembled drills with exchangeable three-flute carbide heads demonstrates an effective balance.

Its unique flute design minimizes any impact on strength and rigidity, enabling significant productivity gains when drilling holes up to 10 times the tool diameter deep.

As a result, the MRR can be increased by up to 50% (Fig. 2).

A Beneficial Combination

In deep drilling, producing narrow chips significantly improves chip evacuation, enabling higher feed rates and increased productivity.

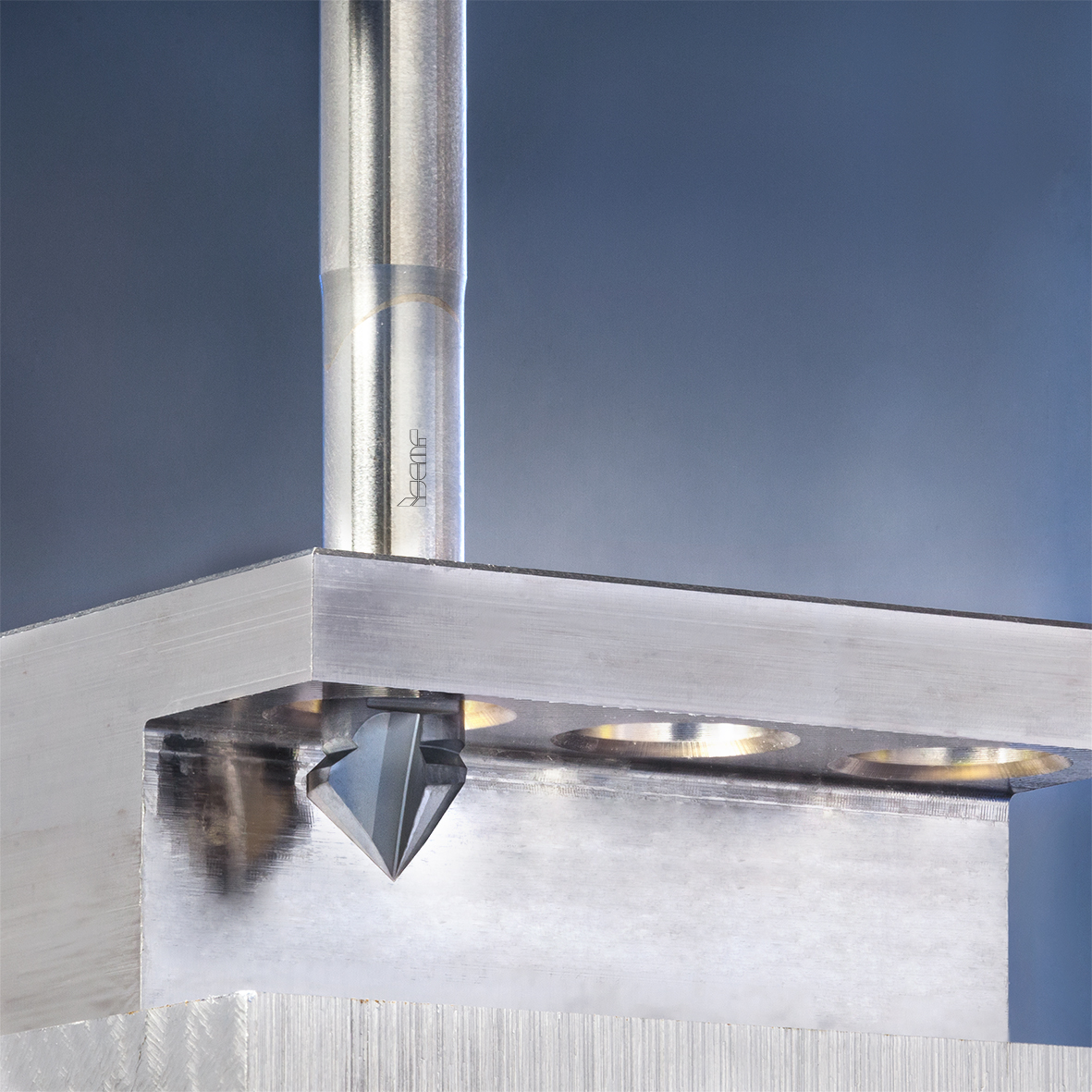

Therefore, to achieve this, a chip-splitting geometry on the cutting edge has been adopted in various ISCAR deep drill designs, particularly in the latest gundrills with replaceable carbide inserts of TRIDEEP line

(Fig. 3).

These inserts incorporate a main cutting edge with a chip-splitting design and a secondary wiper edge intended to provide a fine surface finish.

The inserts are made from the advanced IC948 carbide grade.

Compared to previous gundrill designs, the new tools offer a reinforced body to enhance strength and prevent deflection.

The combination of the chip-splitting effect, advanced carbide grade, and reinforced body structure greatly contributes to higher MRR when drilling deep holes.

Tools in the standard gundrill line are designed for productive machining of holes with a depth-to-diameter ratio of up to 25.

Additionally, ISCAR offers customized TRIDEEP solutions for drilling to depths of up to 1650 mm (65").

Deep drilling has long been a truly "deep problem" - a significant challenge for manufacturers.

However, ISCAR’s new tools offer reliable solutions to overcome this challenge and make deep drilling operations much more efficient.